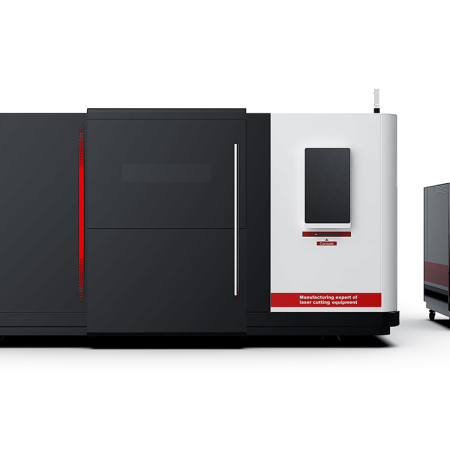

A metal sheet laser cutting machine is a high-tech industrial machine that uses a laser beam to cut metal sheets of various sizes and thicknesses. The machine uses a focused laser beam to melt, burn, or vaporize the metal, leaving a clean and precise cut.

Here are some of the key features and capabilities of a metal sheet laser cutting machine:

Precision: Laser cutting is a precise method of cutting that allows for accurate and consistent cuts, reducing the need for additional finishing work.

Speed: Laser cutting is a fast process that can produce high-quality cuts in a short amount of time, increasing productivity and efficiency.

Versatility: A metal sheet laser cutting machine can be used to cut a variety of metals, including steel, aluminum, and copper, as well as other materials such as plastics and wood.

Customization: Laser cutting can be used to create intricate designs and shapes, making it ideal for creating custom parts and components for a wide range of applications.

Automation: Metal sheet laser cutting machines can be automated to operate continuously, reducing the need for manual labor and increasing productivity.

Safety: Laser cutting machines require proper safety precautions to prevent eye damage and skin burns. Operators must wear appropriate protective gear, such as goggles and gloves, when using the machine.

Overall, a metal sheet laser cutting machine is a powerful and versatile industrial machine that can produce high-quality cuts quickly and accurately. Metal Sheet Laser Cutting Machine supplier It requires proper safety precautions and maintenance to ensure safe and efficient operation.

Features and Functions of Metal Sheet Laser Cutting Machine

A metal sheet laser cutting machine is a highly advanced industrial machine that offers several features and functions.

Here are some of the key features and functions of a metal sheet laser cutting machine:

Laser cutting head: The laser cutting head is the main component of the machine that houses the laser source and focuses the laser beam onto the metal sheet. It is designed to move in multiple directions, allowing for precise and accurate cutting.

Material handling system: The material handling system is responsible for moving the metal sheet into position for cutting. It may include a conveyor belt, pallet changer, or other automated systems.

Control system: The control system is the brain of the machine, responsible for controlling the movement of the laser cutting head and material handling system, as well as the laser source and other components.

Laser source: The laser source is the heart of the machine, providing the energy needed to melt, burn, or vaporize the metal sheet. The laser source may use a CO2 laser or fiber laser, depending on the application.

Software: The software is used to program the machine and create cutting paths for the laser cutting head. It may include CAD/CAM software or other specialized software for laser cutting.

Cooling system: The cooling system is responsible for regulating the temperature of the laser source and other components, preventing overheating and ensuring optimal performance.

Safety features: A metal sheet laser cutting machine has several safety features, such as interlocks, emergency stop buttons, and protective enclosures, to prevent accidents and ensure operator safety.

Overall, a metal sheet laser cutting machine is a highly advanced industrial machine that offers several features and functions to enable precise and efficient cutting of metal sheets. It requires proper safety precautions and maintenance to ensure safe and efficient operation.